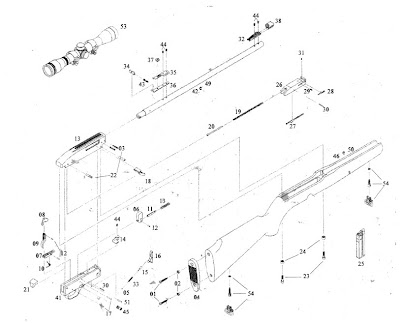

Vista Explodida Nylon 66 Disassembly

Understand that the need for you to know the specific kind of every driver you are interested in grabbing is totally redundant and the moment you are considering utilizing an automatic scanner that accomplishes this all for you and requires zero direction or configuration on your behalf. Under-going an os up grade is one of typical scenario in which a driver scanner becomes essentially essential, since it offers to revise the complete archive of drivers making them ready to accept the recent windows type. Descargar drivers conceptronic c54ru windows 7 7. The high availability, low price, and high productivity of auto driver scanner applications makes them the common remedy for pc users intent on maintaining their units at high operation level. Searching for the relevant updated driver over the internet can be quite a tough task, since many drivers will not be readily accessible, and those that are may not be readily located. While taking care to modernize Conceptronic CLLCHATCAM Webcam is without a doubt essential, you need not forget about all the other drivers, that your choice of devices make use of for the optimal operation of your hard drive or laptop.

• 1 Answer SOURCE: IMPORTANT Recall info: WINCHESTER MODEL 100 FIRING PIN RECALL - A notice dated 7-1990 relates the following “PRODUCT SAFETY WARNING AND REPLACEMENT NOTICE. Attention owners of Winchester model 100 rifles and carbines please read this notice. In July of 1990 the following product safety warning was issued by Winchester. It has come to our attention that the firing pin in the Winchester Model 100 Rifle or Carbine may break due to use and metal fatigue and become lodged in the breech bolt face.

If this occurs, the firearm may fire before the action is locked causing severe damage to the firearm and possibly injury or death to the shooter and bystander. WARNING DO NOT SHOOT YOUR WINCHESTER MODEL 100 RIFLE OR CARBINE. Repair and replacement. A new firing pin has been designed to replace the firing pin originally made for the Winchester Model 100 Rifle and Carbine. The new firing pins will be available in April 1991. If you own a Winchester Model 100 Rifle or Carbine, please send your firearm to one of the authorized Winchester Model 100 Firing Pin Replacement Centers indicated below.

Your Winchester Model 100 firearm will be inspected, the firing pin replaced and tested and the firearm returned to you. The inspection, replacement/testing and return postage will be accomplished at no cost to you. If other repair or maintenance work is authorized by you to be performed on the firearm when the firing pin is replaced, such work shall be at your cost.” W. Long Gunsmiths 2007 Brook Road North Cobourg, Ontario K9A4W4 Canada Frank LeFever & Sons RD 2 Box 31 Lee Center, NY 13363 USA Bolsa Gunsmithing 7404 Bolsa Avenue Westminister, CA 92683 USA Nu Line Guns 1053 Caulks Hill Road Harvester, MO 63303 USA If you have any questions concerning this notice, call Winchester Product Service 1-800-852-5734 or write to Winchester Firing Pin replacement Notice, PO Box 10 Cottage Hills Illinois 62018 Attention Product Service Dept. ---------------------------------------------------------------------------------- The following is Wisner's rendition & info on the subject.

Remington Nylon 66 Disassembly

Rockshox Service Manuals 2009 - Download as PDF File (.pdf), Text File (.txt) or read online. Spray upper tubes with isopropyl alcohol and wipe with a clean rag (not pictured). -016-000 REV A. Black nylon crush washers and crush wash retainers. -016-000 REV A. Shock body disassembly spring spring. If you not sure which model of Remington Nylon 66 you have check out wikipedia and you should find your answer there or find a local gun expert. Assemble and disassembly of the Remington nylon 66? PLEASE HELP NYLON 66. Discussion in 'Rifle Country' started by retirednow, Nov 29, 2005. Thread Status: Not open for further replies. These parts on other Nylon 66 rifles are blued. 1 Before disassembly, make sure rifle is unloaded. Engage safety (36) on safe position to rear. Pull bolt handle. UDOR KAPPA Series Diaphragm Pumps. KAPPA-7, 15, 18 Have Glass Filled, Nylon Heads. Three and four diaphragm pumps include mounting rails. Pump Speed - 540 RPM. Hose Barb Ports Max. Manual dump valve, dual ball valve outlets & pressure gauge. Equipped with a 25 mm keyed shaft & mounting rails.

The difference in the old firing pin and the new one is as follows. Drivers para lexmark p3150 windows 7. The old replaced style, was totally lathe tuned (round). While the new recall style is similar in lathe turning on the front and back, but in the front midsection it has two flats milled, one on each side.

Nylon 66 Value

This makes the center section stronger. Also replaced is the bolt sleeve lock pin (firing pin guide) which was made to accommodate this different shaped firing pin Part number for the new parts are, firing pin =1391ND, bolt sleeve locking pin =1491ND The word was at the time this recall was in process was that if the firing pin would break at the mid section and still remain in the gun as two pieces, the possibility of a premature discharge before the bolt was locked was possible. This apparently was caused by the firing pin tip (now not having a retracting spring) to be stuck forward, and thereby slam-firing upon chambering. The responsibility for the recall apparently was on Olin, as they were the parent company at time of manufacture. Olin set up regional recall centers at three established US gunshops. There was a manufacturing delay in the replacement firing pins, and a backlog occurred, also some collectors did not like the idea of shipping their guns long distances. Olin then also authorized other gunshops to make the required alterations.

Upon completion of the recall, the shops were to test fire the firearm and to stamp an assigned letter on the inside top of the receiver as seen thru the magazine well with the bolt retracted. The letter “B” represented Bolsa Gunsmithing, “L” was Lefever, and “N” was for Nu-line Guns. The letter “X” apparently was for all the other independent shops. However this identification information did not get communicated to some of the smaller shops at the start of the project. The only way to tell if the gun as been modified, if the ”letter” is not present, is to take the barrel & action out of the stock, remove the trigger guard assembly and the try to rotate the firing pin by twisting it. If it does NOT rotate, then the firing pin recall HAS been performed.